Packaging materials form the way products are preserved, advertised, and taken. With industries worrying sturdiness, barrier safety, and rate-effectiveness, one query remains steady—which Film plays fantastic? Among the numerous alternatives to be had, metallized PET film has come to be a bypass-to answer. But how does it have a look with specific packaging Film which incorporate polyethylene, polypropylene, or aluminum foils? Let’s dive deep into the versions, benefits, and traumatic situations of those substances.

What is Metallized PET Film?

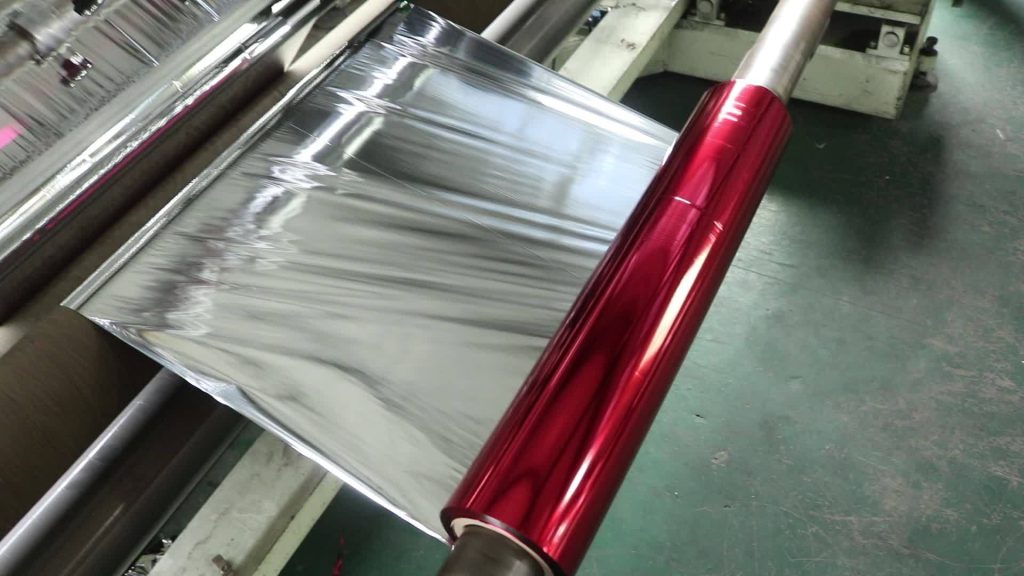

At its middle, metallized PET Film is a polyester film coated with a skinny layer of metallic—normally aluminum—the use of a gadget called vacuum metallization. This treatment creates a shiny, reflective floor at the same time as maintaining the capability of PET. It is appreciably carried out in meals packaging, electronics, labeling, and insulation because of its light-weight but sturdy barrier homes.

Unlike normal Film, metallized PET offers advanced oxygen and moisture resistance. This is vital in extending product shelf existence, specially inside the meals and pharmaceutical sectors.

How Vacuum Metallization Enhances PET Films

The mystery in the return of metallized PET’s time-honored average ordinary overall performance lies in vacuum metallization, a way that includes evaporating aluminum inside a vacuum chamber and depositing it lightly on the PET ground. This treatment offers PET films specific houses:

- High reflectivity – beneficial in every packaging and insulation.

- Excellent barrier conventional average standard performance in competition to gases, slight, and moisture.

- Lightweight but durable as compared to bulkier alternatives like aluminum foil.

For industries demanding each aesthetics and function, vacuum metallization makes PET films stand out. To discover more approximately how metallization affects protecting packages, you could take a look at vacuum metallization.

Metallized PET Film vs. Polyethylene (PE) Films

Polyethylene Film are the most inexpensive and most common packaging substances. They are bendy and smooth to approach, but at the equal time as in evaluation to metallized PET film, their limitations are smooth:

- Barrier homes: PE offers horrible resistance to oxygen and moisture. Metallized PET, however, gives advanced safety.

- Durability: PE is at risk of tearing and punctures, at the identical time as PET films are more potent and in addition resilient.

- Appearance: PE lacks the easy steel prevent that metallized PET can deliver, making PET more appealing for branding and pinnacle magnificence packaging.

In industries in which shelf lifestyles and logo appeal are important, metallized PET is the smooth winner.

Metallized PET Film vs. Polypropylene (PP) Films

Polypropylene Film are each different well-known choice in packaging because of their clarity and charge performance. But does PP outperform metallized PET?

- Heat resistance: Metallized PET can address higher temperatures than PP, which has a tendency to warp or degrade below warmness.

- Shelf life: PET Film notably increase product existence via maintaining oxygen and moisture out, at the equal time as PP calls for added coatings or laminates.

- Recyclability: Both substances can be recycled, but metallized PET’s multi-useful use makes it greater sustainable in excessive-barrier packaging packages.

For programs that require every barrier performance and sturdiness, metallized PET film but holds the threshold.

Metallized PET Film vs. Aluminum Foil

This evaluation is the most debated. Aluminum foil has extended the gold ultra-modern in excessive-barrier packaging, but metallized PET film offers a lighter, more bendy possibility.

- Weight: PET Film are extensively lighter, decreasing transportation fees.

- Flexibility: Unlike stiff aluminum foil, PET films can observe complicated packaging designs.

- Barrier popular preferred common performance: Aluminum foil gives the best barrier, however metallized PET comes close to, making it terrific wherein weight and flexibility rely.

- Cost performance: PET films are typically inexpensive in huge-scale packaging applications.

While aluminum foil, despite the fact that it dominates in prescription drugs and distinctly touchy gadgets, metallized PET is an increasing number favored in meals, electronics, and purchaser packaging.

Why Metallized PET Film Stands Out

So, what makes metallized PET film an exquisite desire in the course of industries?

- Barrier safety – Prevents product spoilage and contamination.

- Cost-powerful possibility – Lighter and much less steeply-priced than aluminum foil.

- Aesthetic attraction – Shiny, reflective ground enhances branding.

- Durability – Stronger than preferred PE or PP Film.

- Versatility – Used in packaging, labels, insulation, and electronics.

These skills deliver a reason for why industries internationally are transitioning in the course of the vacuum metallizing era for PET-primarily based packaging solutions.

Applications Beyond Packaging

metallized PET Film are not handiest for food packaging. They are essential in:

- Electronics protective – lowering electromagnetic interference. For instance, industries use shielding tape made from metallized PET for sensitive digital applications.

- Thermal insulation – reflecting warmth in advent and car industries.

- Decorative finishes – presenting high priced appeal in present wraps and labels.

- Solar and lighting industries – reflecting and diffusing mildly efficiently.

This versatility makes metallized PET one of the most future-evidence films in current-day production.

The Future of Metallized PET Films

With sustainability turning into an international precedent, the call for mild-weight, recyclable, and sturdy packaging substances is developing. Metallized PET films align with this style. Ongoing studies into green vacuum metallization strategies guarantees to make PET films even greener without compromising normal universal overall performance.

As industries shift some distance from heavy aluminum foils and multilayer plastics, metallized PET is about to dominate the following decade of packaging innovation.

Final Thoughts

When comparing metallized PET film with PE, PP, and aluminum foils, one aspect is obvious—PET films offer the best balance among well-known performance, charge, and sustainability. While aluminum holds its area in particular industries, metallized PET maintains upward thrust due to the fact the smarter, lighter, and more bendy preference.

Whether in food protection, electronics safety, or pinnacle magnificence branding, metallized PET film is shaping the destiny of packaging. And as technology improves, it’s going to get better.